The demand for surface cleaning and preparation in the industrial sector is increasing day by day. Choosing the right sandblasting equipment is crucial to meet these requirements. Airblast is one of the proven leaders in this field. But why Airblast?

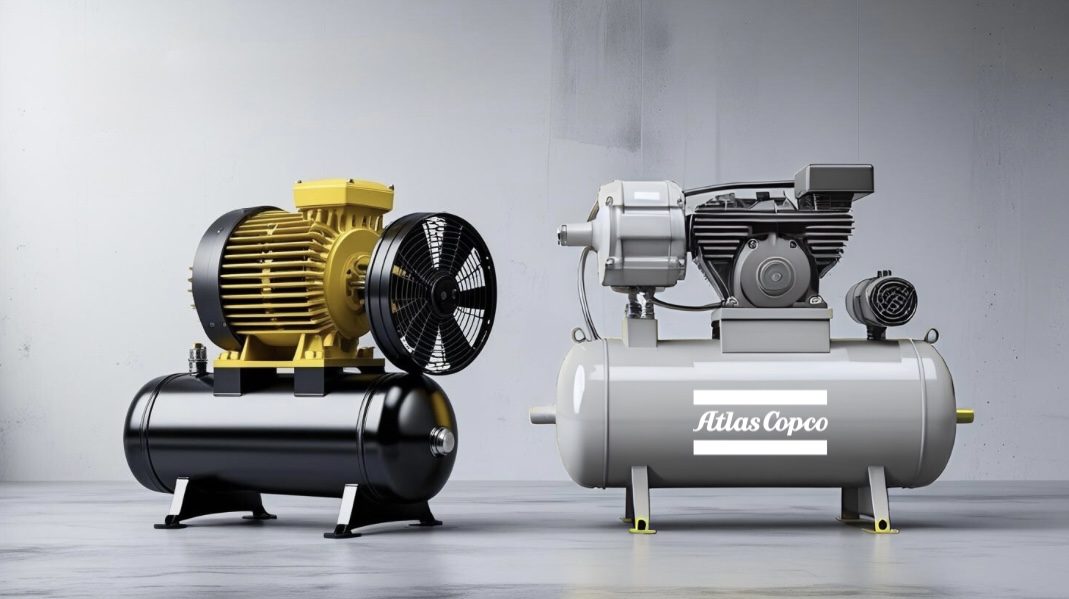

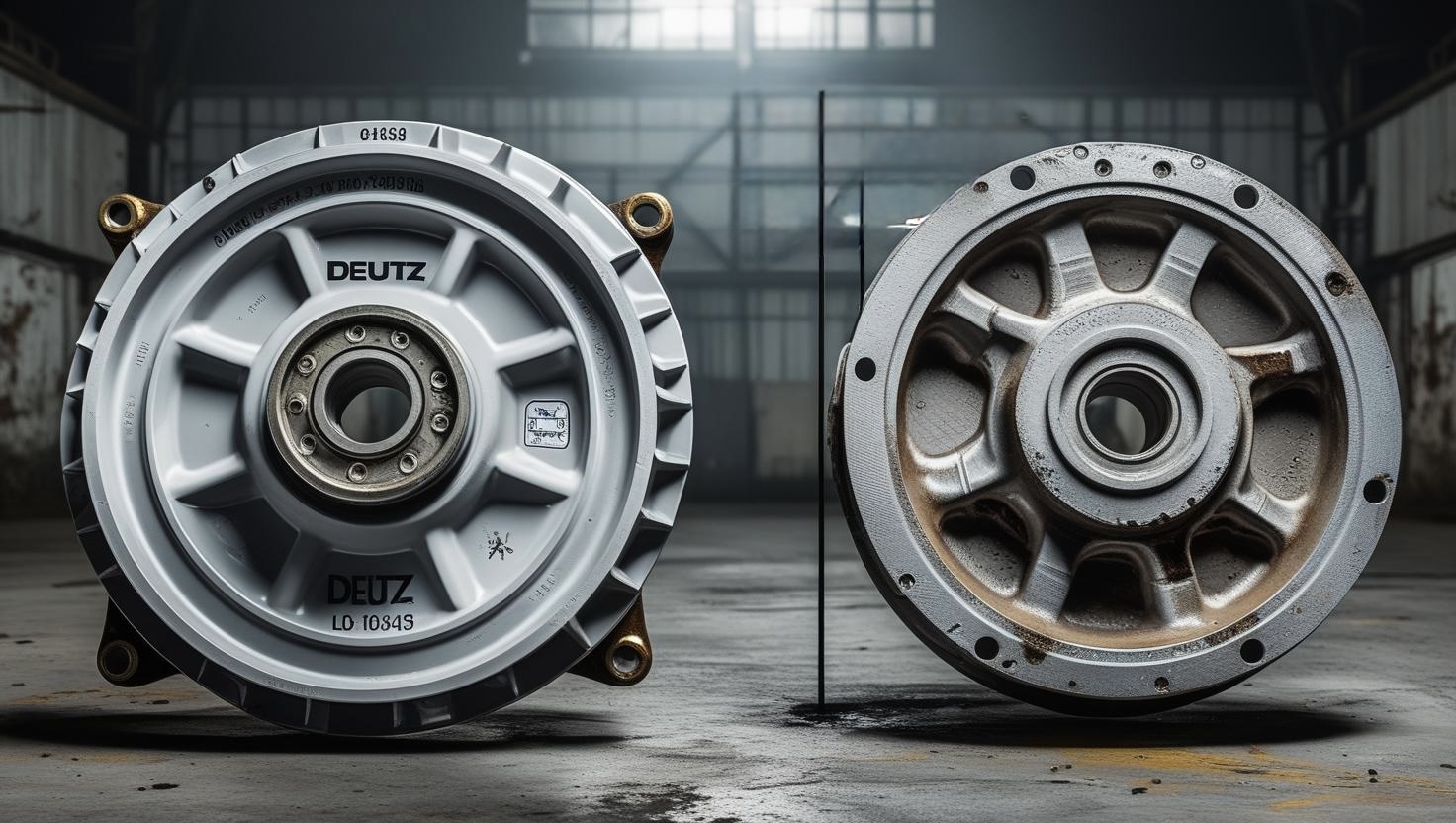

- High-Quality and Durable Construction

Airblast equipment is made from high-quality materials, ensuring long service life and suitability for harsh working conditions. Even in heavy industrial environments, it operates steadily and safely.

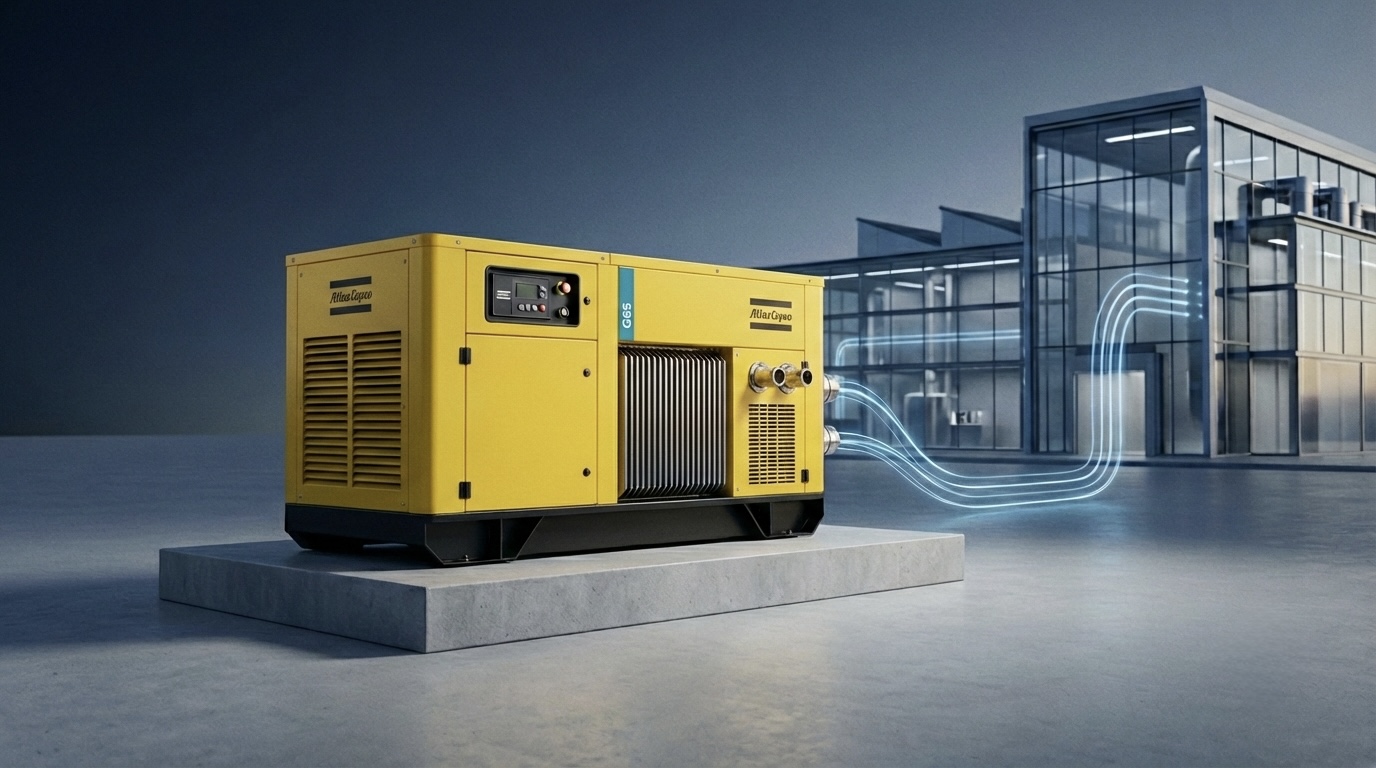

- Precision for Professional Results

Precision is essential in the sandblasting process. Airblast equipment, with its high pressure and precise spraying mechanism, ensures complete and uniform cleaning of the surface. This improves the final quality and creates an ideal base for subsequent layers such as paint or coatings.

- Wide Range of Accessories and Spare Parts

At Atlas, we provide not only Airblast equipment but also all necessary accessories — protective clothing, sandblasting hose, helmet, filter, gloves, and sandblasting gun. This offers you a professional sandblasting package in one set.

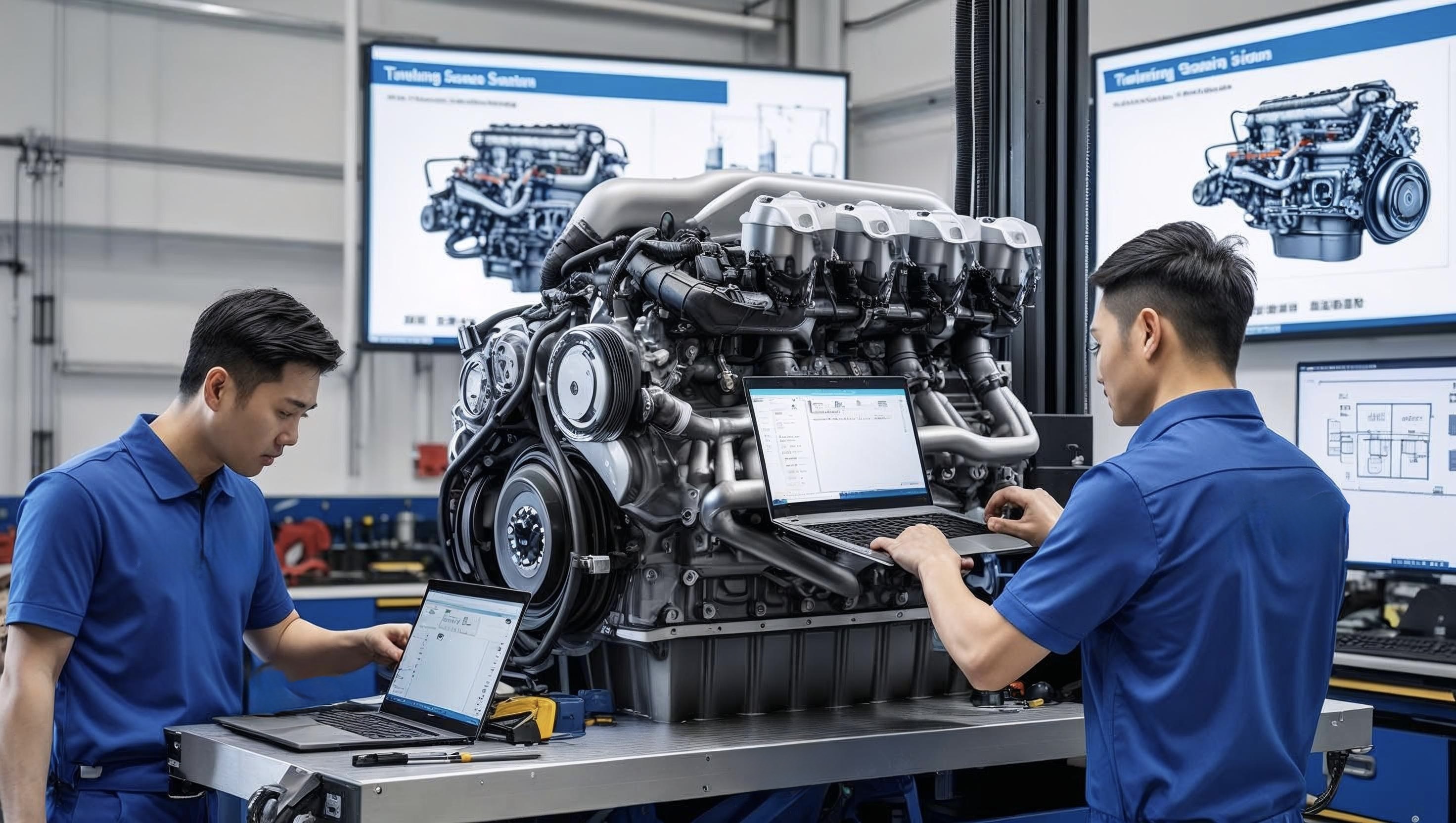

- Safety and Ease of Use

Airblast equipment prioritizes user safety. High safety standards and ergonomic design ensure both operator comfort and work efficiency.

- Atlas – Your Official Partner

We, Atlas, are the official distributor of Airblast in Azerbaijan. We offer only original products, along with technical support, servicing, and spare parts supply, giving you full confidence in your sandblasting projects.

Conclusion

If quality, safety, and precision are important to you when choosing sandblasting equipment, Airblast is the right choice. Atlas offers you reliable partnership and professional solutions in this field.

Looking for reliable and powerful equipment for sandblasting? Contact us! Achieve faster and more efficient results with Airblast!

Contact: +99451-232-55-55

More info: www.atlas.az