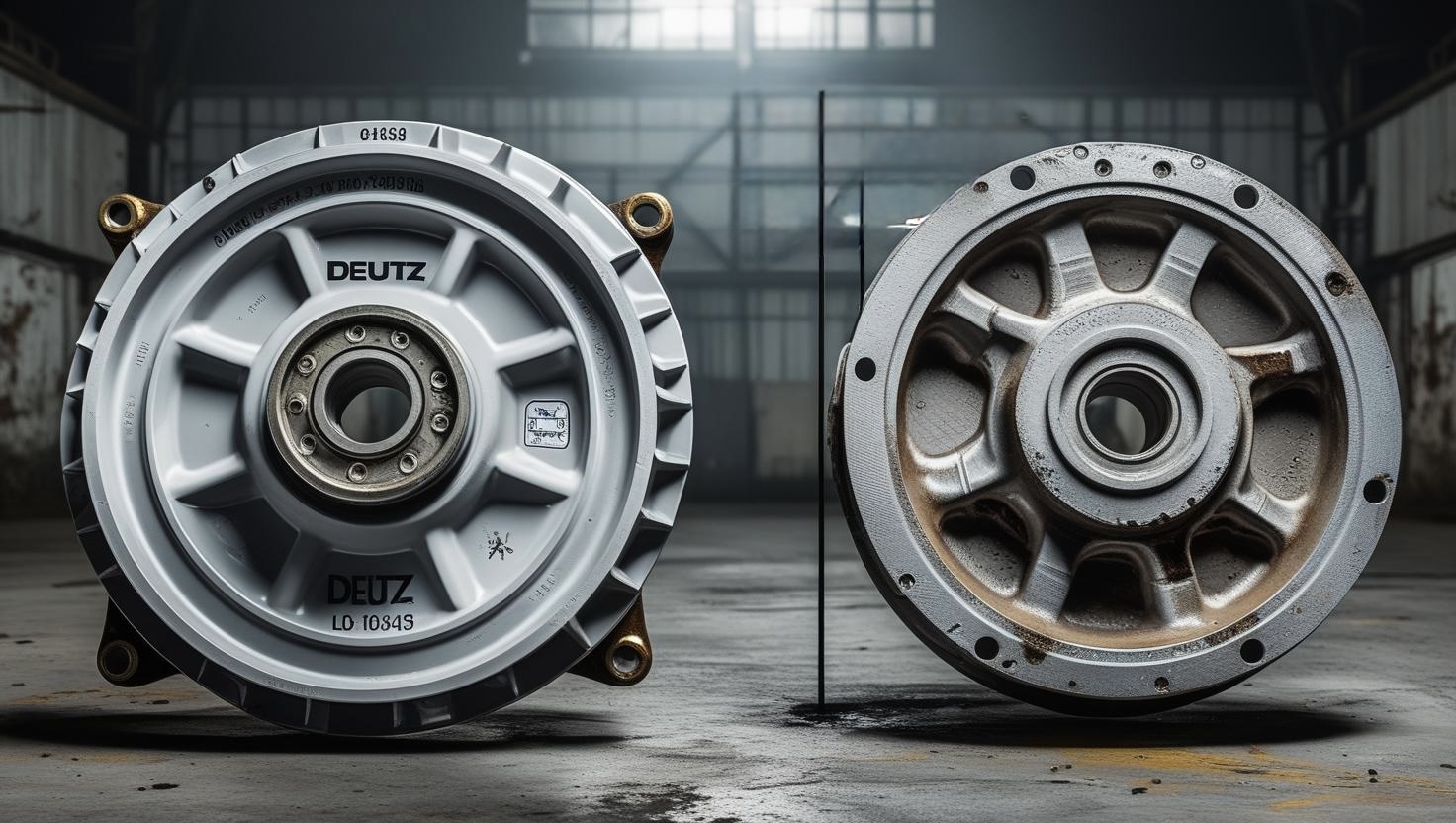

Genuine vs. Counterfeit Spare Parts: What Really Matters for Your Deutz Engine?

When it comes to industrial equipment, especially high-performance machines powered by Deutz engines, reliability is everything. But what many operators don’t realize is that the health of the engine depends not only on how it’s used — but also on the quality of the spare parts installed.

So, what’s the real difference between genuine and counterfeit Deutz spare parts? And why should you always choose original?

Let’s break it down:

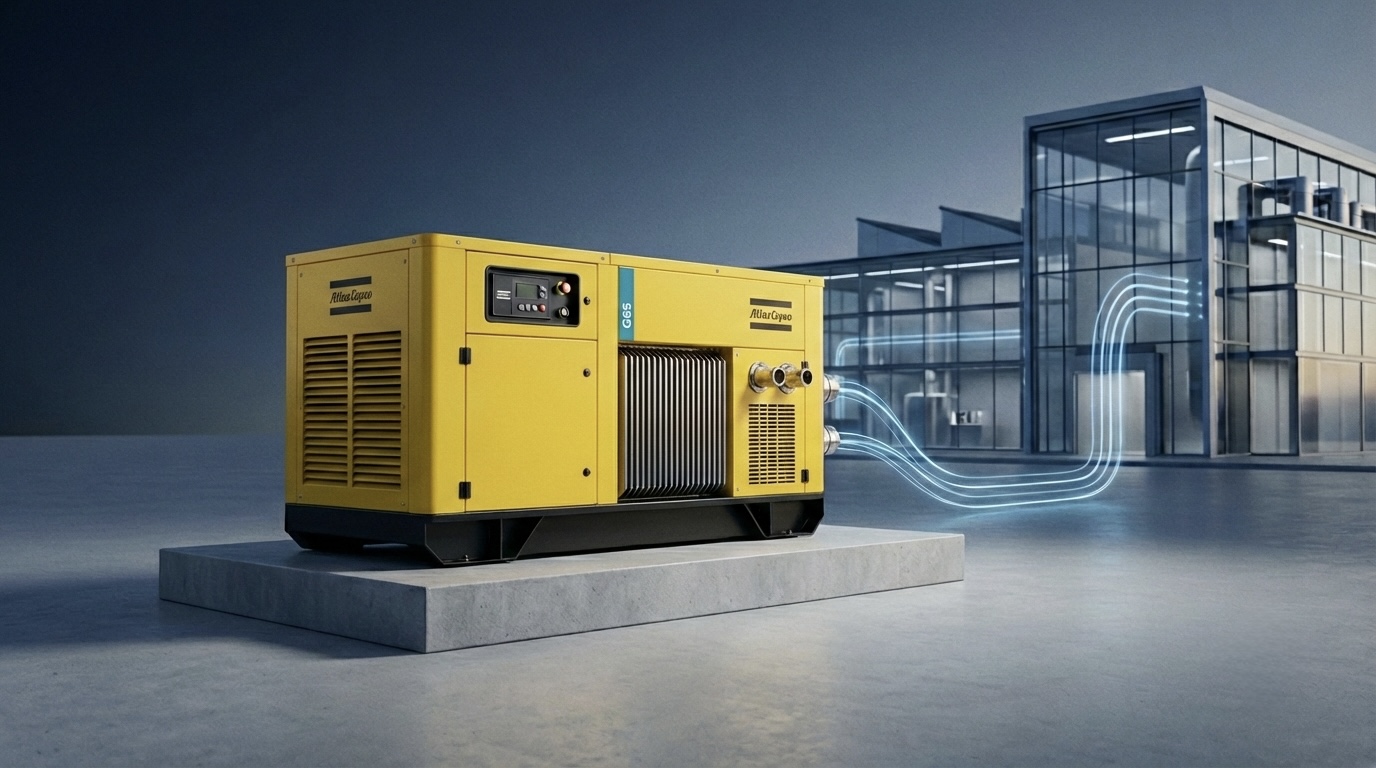

1. Material Quality and Durability

Genuine Deutz parts are produced under strict quality standards, using durable, wear-resistant materials tailored to the specific engine model.

Tested in factory conditions

Designed to last longer

Fully compatible with Deutz systems

Counterfeit parts, on the other hand:

Are made of cheaper, low-quality materials

Wear out quickly

Cause engine inefficiency or even failure

Short-term savings can lead to expensive repairs.

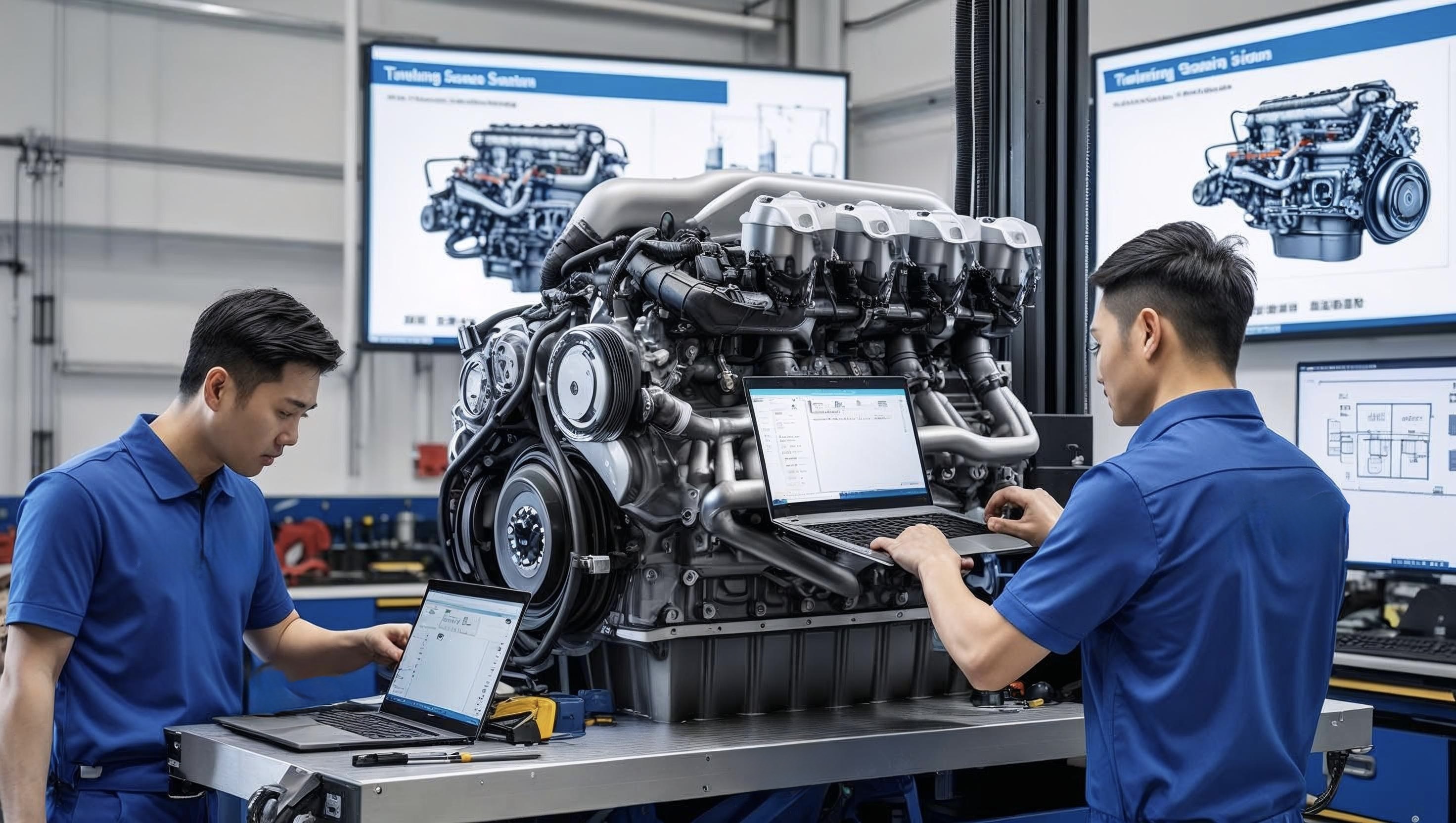

2. No Certified Testing for Fake Parts

Genuine parts go through:

- Rigorous testing

- Certification by Deutz AG

- Compliance with emissions and safety standards

Fake parts:

Are not tested

Lack traceability and documentation

May damage other engine components

3. Warranty Risk

Installing counterfeit parts in your Deutz engine:

- Voids the official warranty

- Disqualifies you from authorized technical support

- Reduces the resale value of your equipment

At Atlas, we only supply 100% genuine Deutz parts — with full documentation and installation by trained technicians.

4. False Economy: Cheap Now, Expensive Later

Many companies see fake parts as a temporary solution, but this “quick fix” often results in:

- Repeated breakdowns

- Downtime on projects

- Greater long-term costs

Genuine = Safer, Longer-lasting, and More Cost-effective over time.

Conclusion: Engine Safety Starts with Authenticity

If you’re operating Deutz-powered machinery, don’t risk your investment with unverified parts. Trust only official distributors and certified service centers.

Atlas is the official Deutz distributor in Azerbaijan, offering:

- Genuine spare parts

- Certified diagnostics

- Trained technical staff

- Full after-sales support

Contact us:

+994 51 232 55 55

???? Baku, Azerbaijan