7 Steps to Minimize Risks in Industrial Facilities

In production processes, even the smallest interruption can lead to significant financial losses. Power outages, equipment malfunctions, worker safety issues, and other risks can negatively impact both productivity and the company’s reputation.

If you want your industrial facility to operate safely and continuously, these 7 steps are essential.

1. Conduct Regular Risk Assessments

Identify where risks originate — from the production line to energy supply, worker safety, and equipment condition.

Atlas recommends: Update your spare parts list based on the results of your risk analysis to avoid delays in replacements.

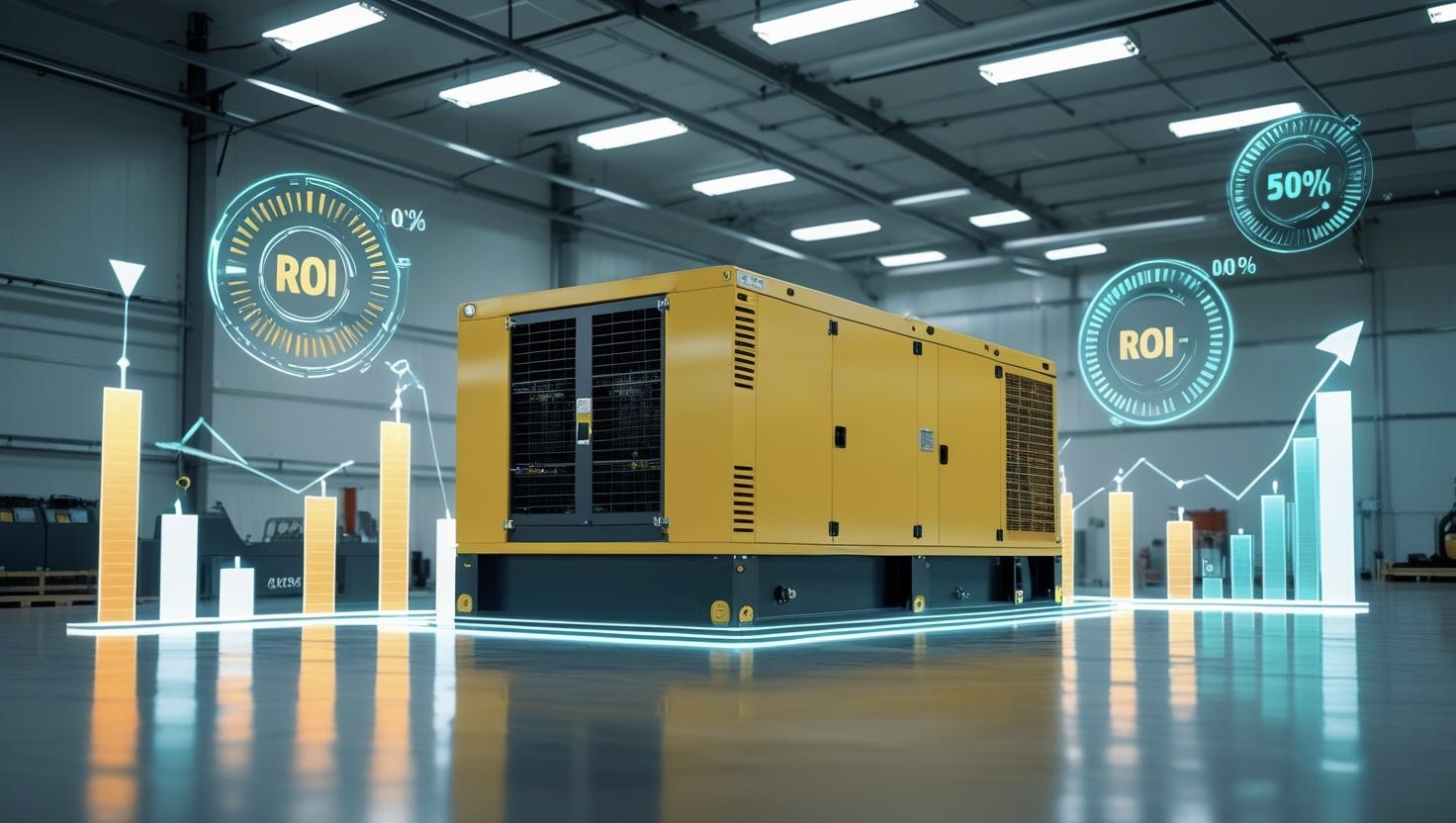

2. Strengthen Power Supply with Backup Sources

Power outages are one of the main causes of downtime in industrial facilities. Reliable electric generators and UPS systems can keep production running without interruption.

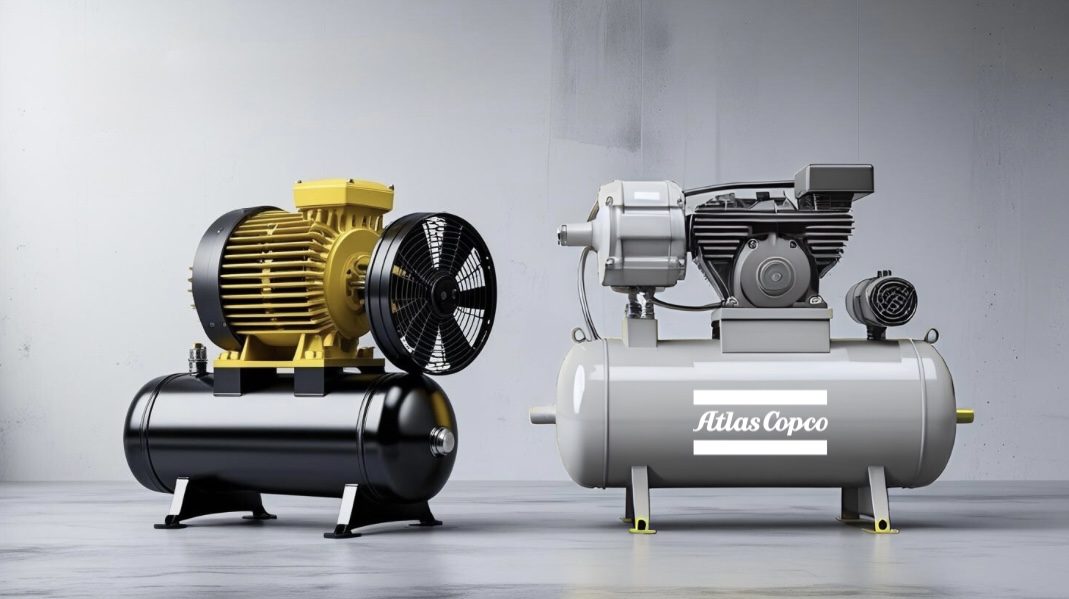

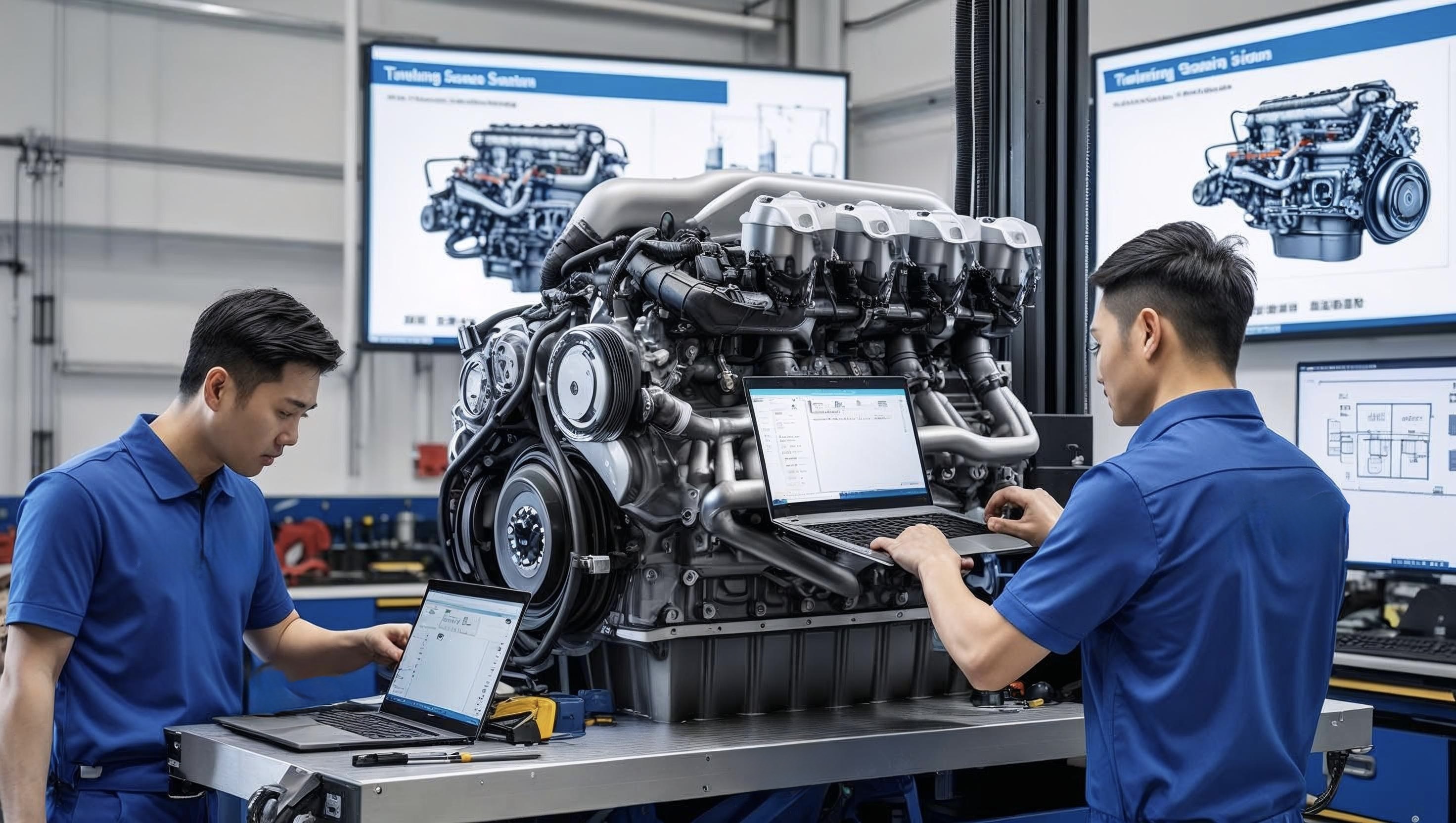

3. Schedule Regular Equipment Maintenance

Preventive maintenance helps avoid sudden equipment breakdowns, ensures continuous production, and extends equipment life.

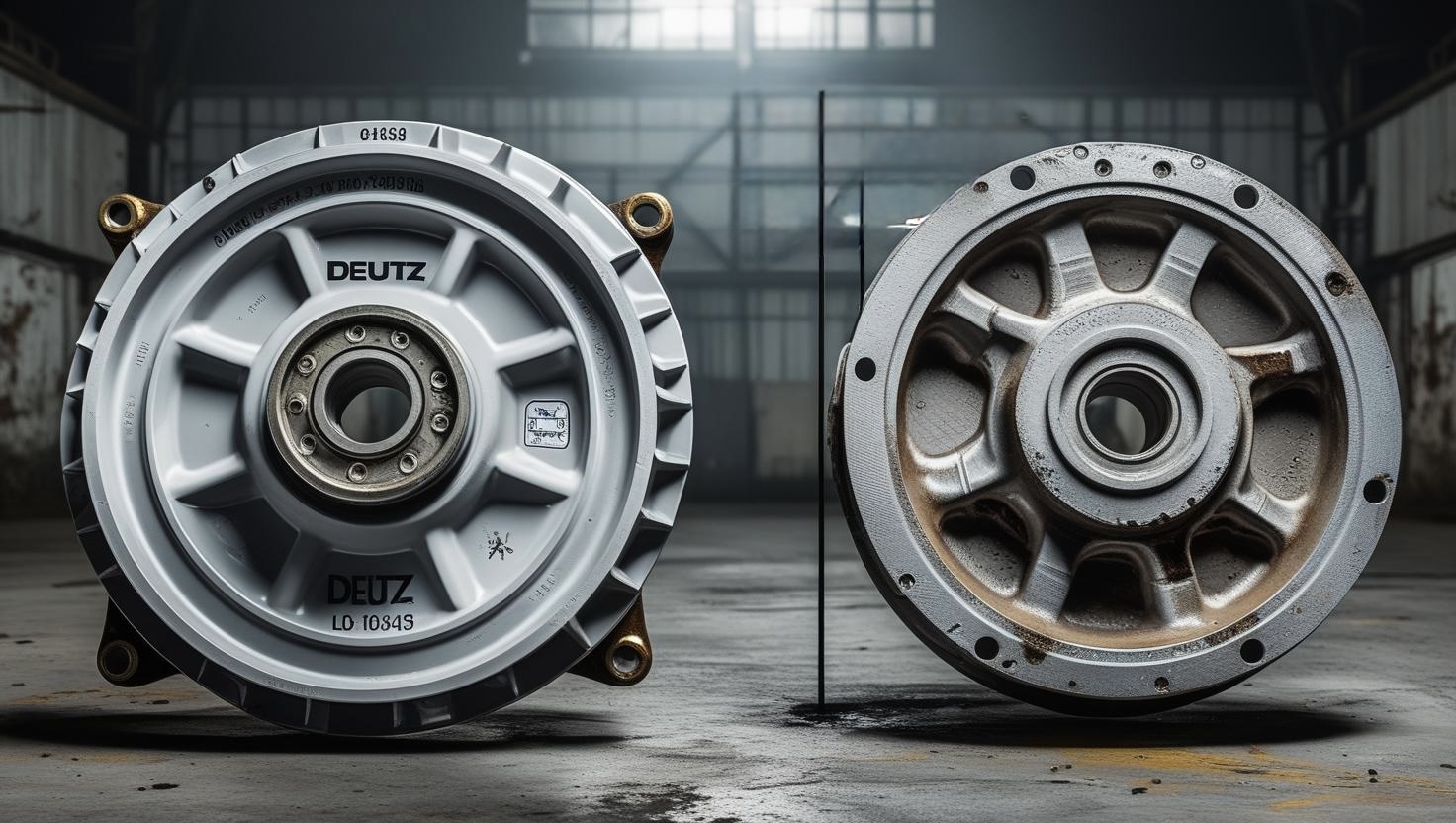

4. Maintain a Spare Parts Inventory

Keep spare parts for critical production equipment in stock to minimize downtime during breakdowns.

5. Enhance Safety Procedures

Worker safety is not only a legal requirement but also crucial for operational continuity. Safety training, protective equipment, and emergency guidelines reduce risks.

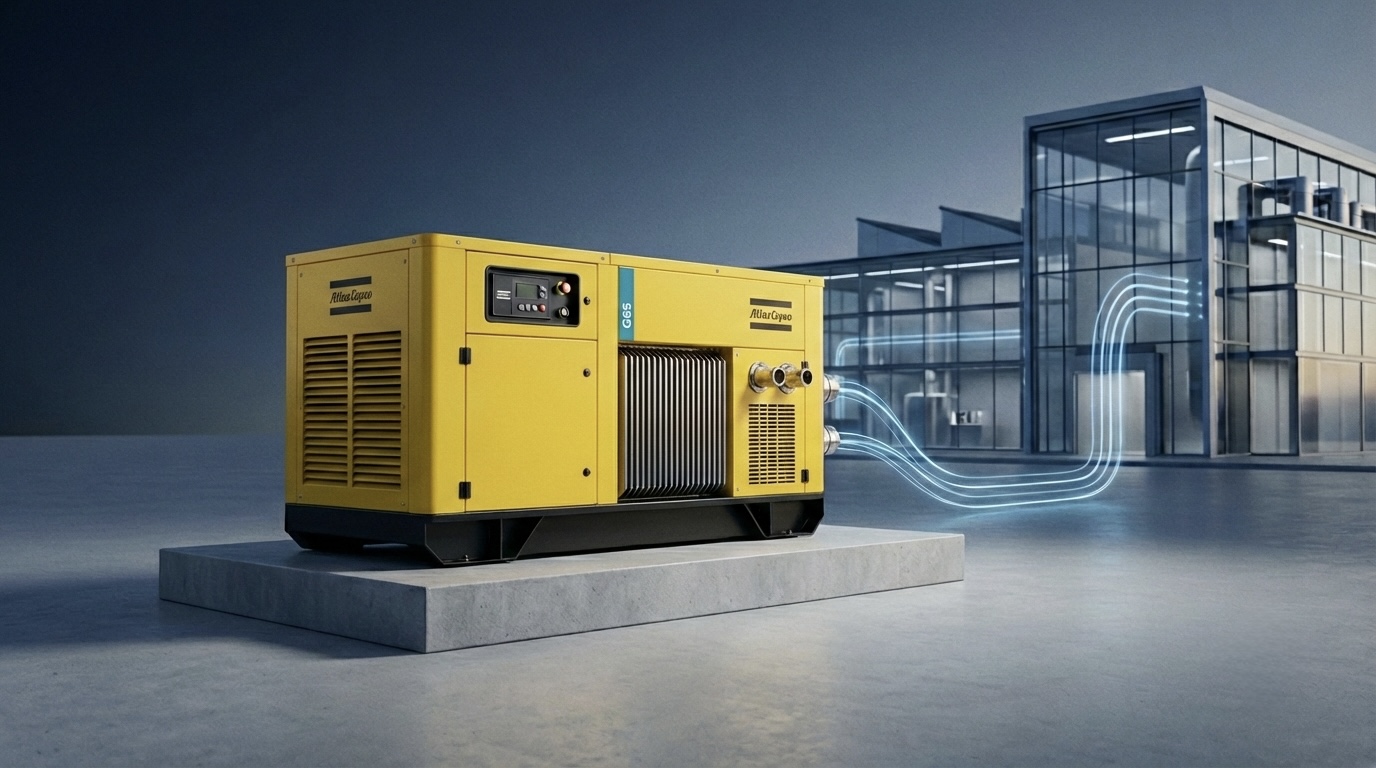

6. Ensure Continuous Air and Compressed Gas Supply

Consistent air pressure is essential for pneumatic tools and production lines. High-quality compressors and backup systems are key.

7. Prepare an Emergency Response Plan

Clearly define the steps to take in case of fire, natural disaster, or technical malfunction to protect your facility from losses.

Conclusion:

By applying these 7 steps, you can minimize risks in your industrial facility and ensure uninterrupted production. Remember, continuity protects not only productivity but also your company’s reputation.

Atlas – Minimize your risks with generators, compressors, and industrial equipment.