Top 5 Common Mistakes During Equipment Repair and Service — And How to Avoid Them

Proper maintenance and timely servicing are crucial for the long-term performance of industrial equipment. However, certain mistakes made during repair or servicing can lead to costly consequences. In this article, we highlight the 5 most common mistakes and share practical tips to avoid them.

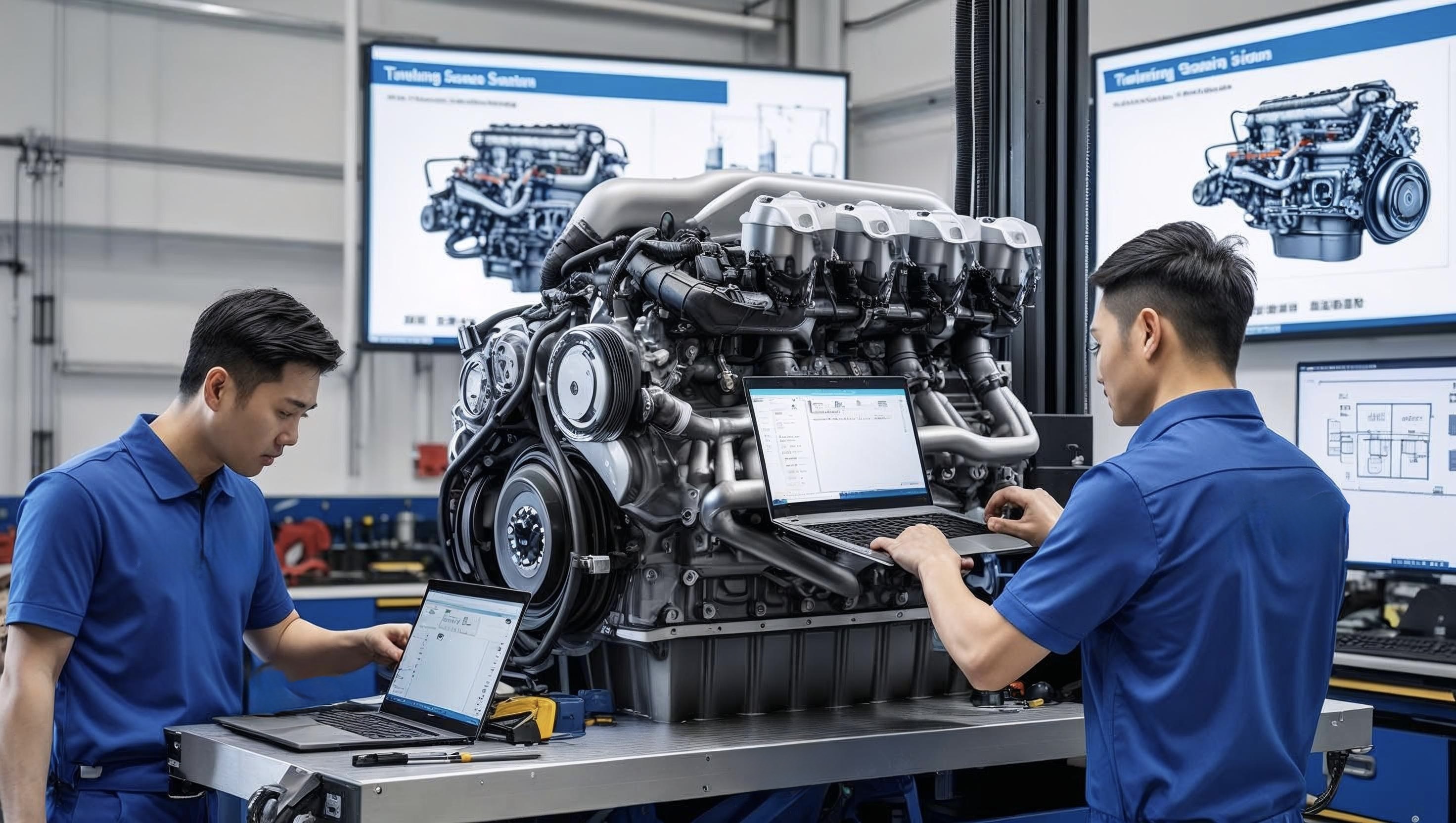

1. Using unauthorized or uncertified repair services

Mistake: Choosing cheap, unofficial technicians to cut costs.

Result: Poor-quality repairs, non-original spare parts, and more breakdowns.

Solution: Always go with certified service centers. At Atlas Service, we only use original parts and trained professionals.

2. Continuing to use equipment despite clear signs of malfunction

Mistake: Ignoring unusual noise, vibration, or performance drops.

Result: Minor issues become major failures.

Solution: Don’t wait — contact service at the first sign of trouble. Early intervention saves time and money.

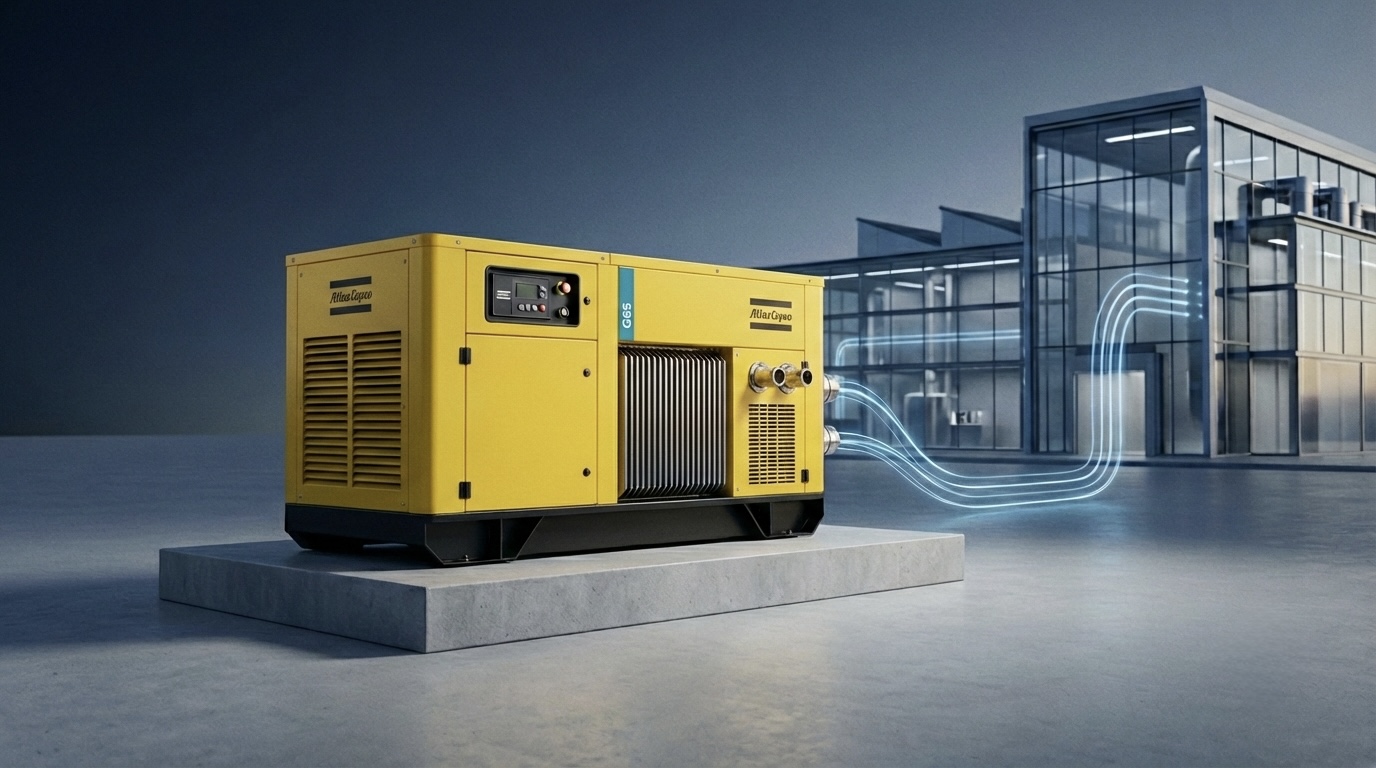

3. Skipping regular maintenance intervals

Mistake: Delaying service just because “it’s still working fine.”

Result: Wear and tear, blocked filters, and overheating.

Solution: Stick to the manufacturer’s maintenance schedule. Atlas offers reminder services to keep you on track.

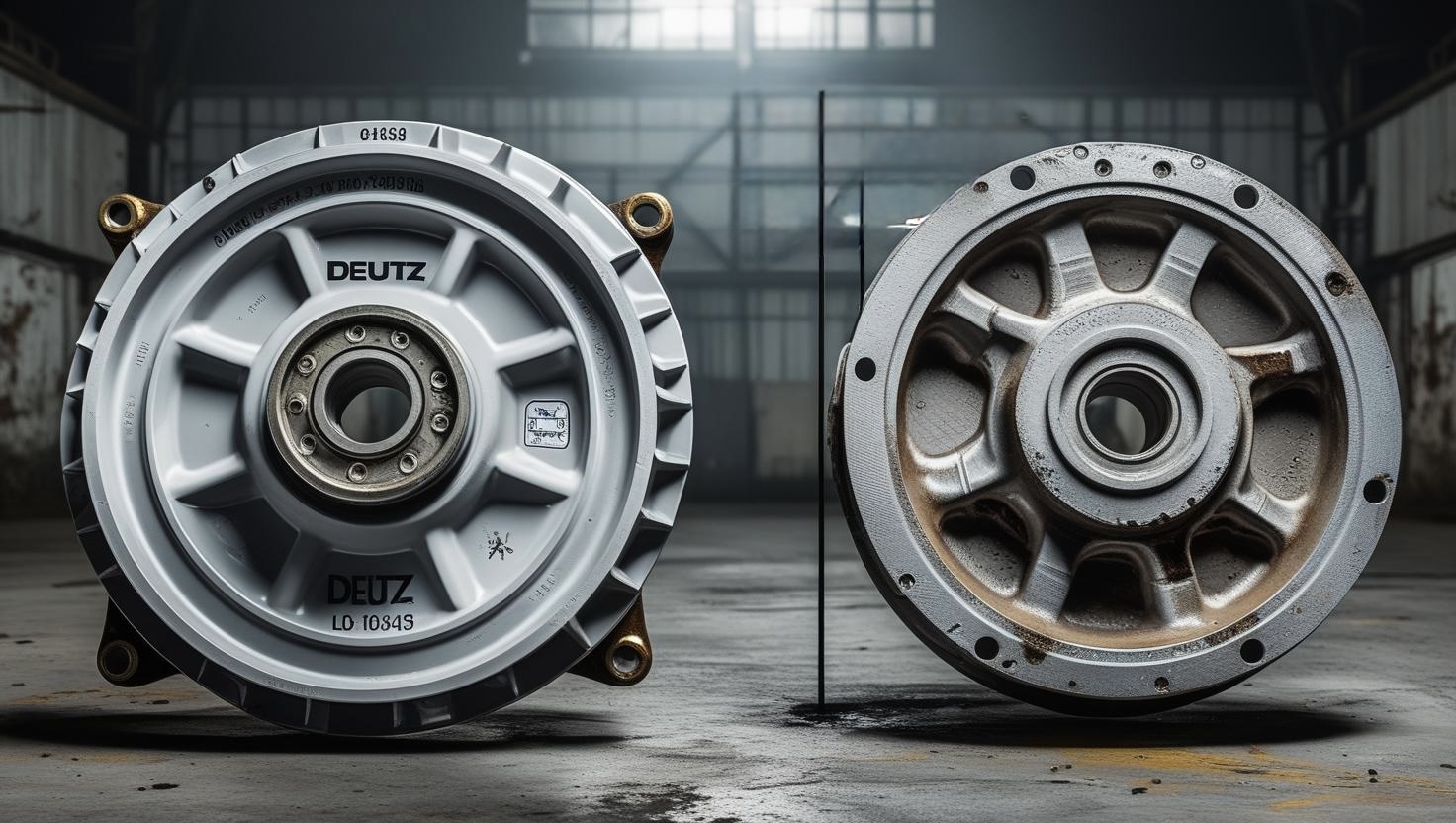

4.Using incorrect oil, filters, or spare parts

Mistake: Choosing cheaper, incompatible parts.

Result: Reduced performance, invalidated warranty.

Solution: Use only original, brand-approved components. Atlas ensures compatibility and quality.

5. DIY repairs without proper knowledge

Mistake: Attempting to fix complex issues via YouTube or guesswork.

Result: Further damage, safety hazards.

Solution: Always consult a qualified technician. Atlas provides both on-site and mobile technical support.

Conclusion: A trusted service is the foundation of long-term equipment reliability.

At Atlas, we don’t just fix machines — we help our customers work without interruptions and ensure lasting performance with care and professionalism.

Contact us:

+994 51 232 55 55