Compressed air is one of the main energy sources in almost all industries today. From car services to large manufacturing plants, many processes depend on the uninterrupted and stable operation of compressors. However, one of the most common problems in practice is the selection of a compressor with a power that does not match the area of use.

An incorrectly selected compressor can lead to both excess energy consumption and rapid equipment failure. In this article, we explain what power and type of compressor is more suitable for different areas.

Why is the choice of compressor so important?

The choice of compressor does not end with the question of “how many kW?” The main issue is how and how intensively the compressed air will be used. Air consumption, operating pressure, daily operating hours and air quality requirements are directly related to each other.

If the compressor is selected weaker than the real need, the system will be constantly loaded and stop frequently. On the contrary, a compressor that is more powerful than necessary means additional electricity costs and ineffective investment.

Car service stations and small workshops

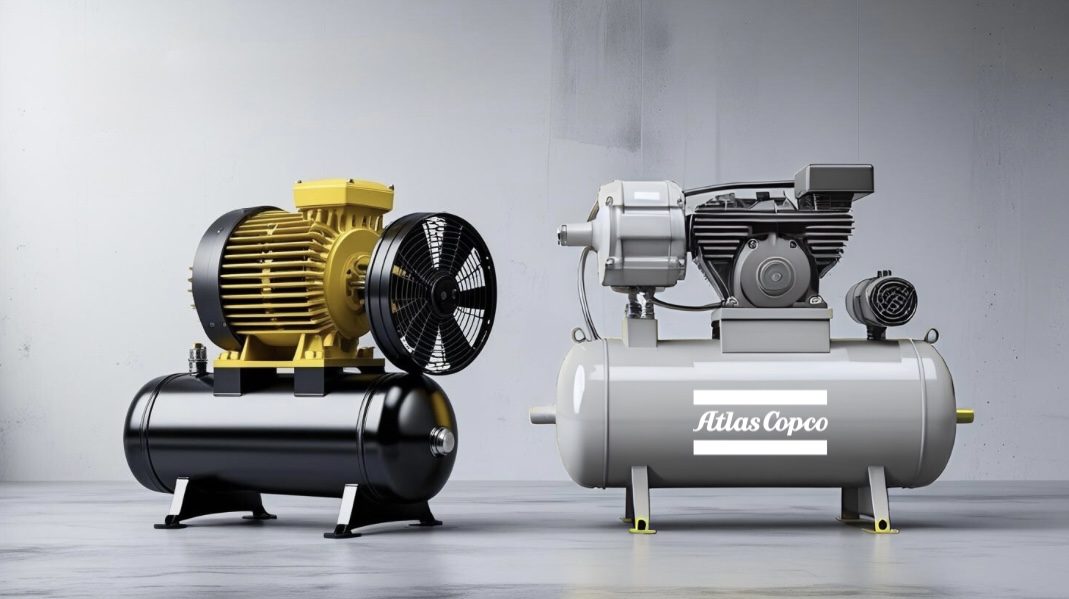

Compressors in car service stations are mainly used for operating pneumatic tools, tire inflation and painting. Since such facilities usually do not operate a large number of equipment at the same time, high power is not required.

Piston or small screw compressors in the power range of 5.5–15 kW, providing a pressure of 8–10 bar, are sufficient for such areas. This option ensures both stable operation and helps to control electricity costs.

Construction and road works

Compressors in the construction sector operate in heavy and continuous mode. Concrete breakers, drilling equipment and pneumatic hammers require high air consumption. Moreover, since these works are usually carried out in open areas, mobile solutions are preferable.

For this reason, diesel and mobile compressors with a power of over 20 kW and a pressure of 10–12 bar are more appropriate in the construction sector. The main priority here is durability and compatibility with harsh operating conditions.

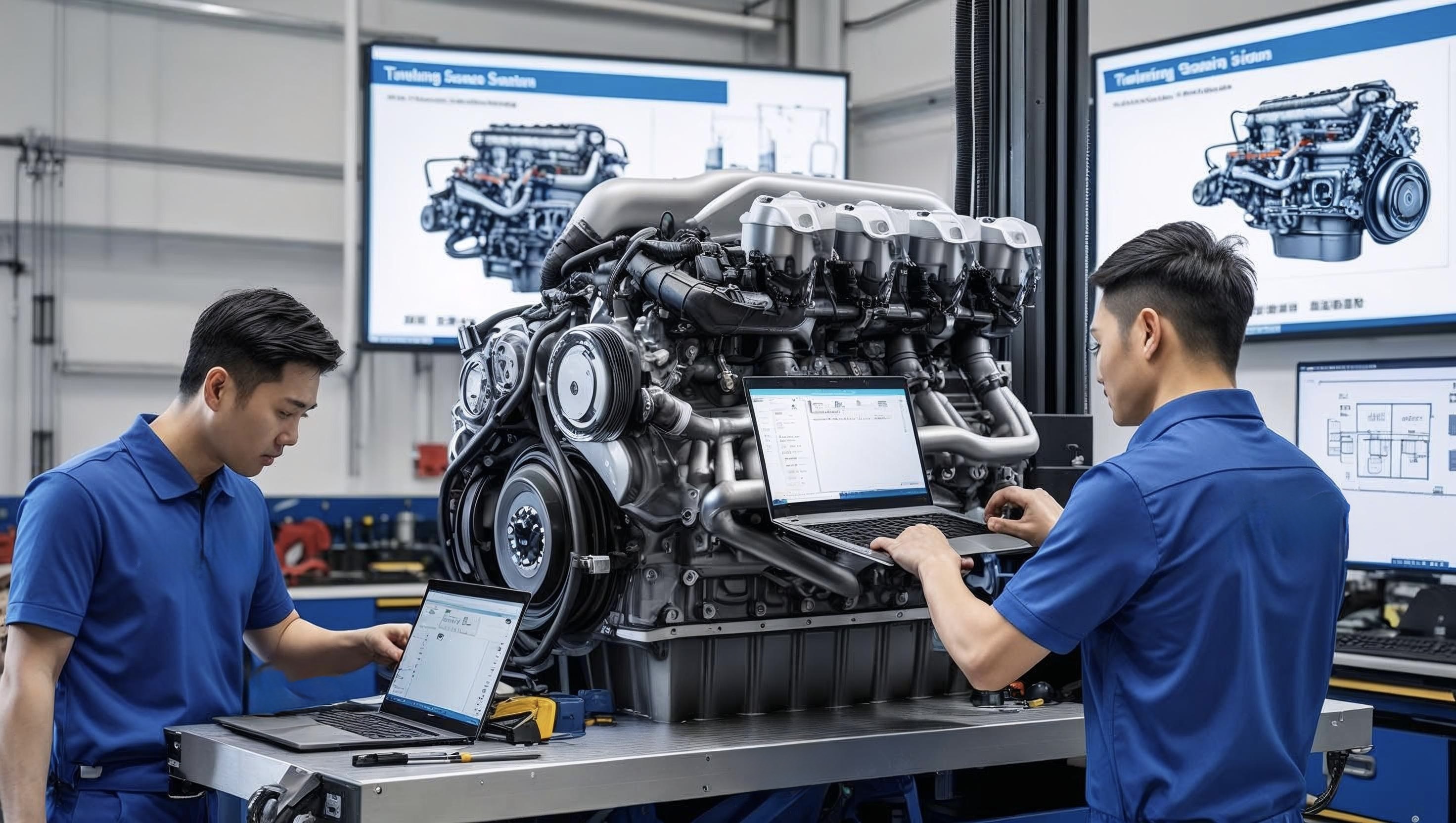

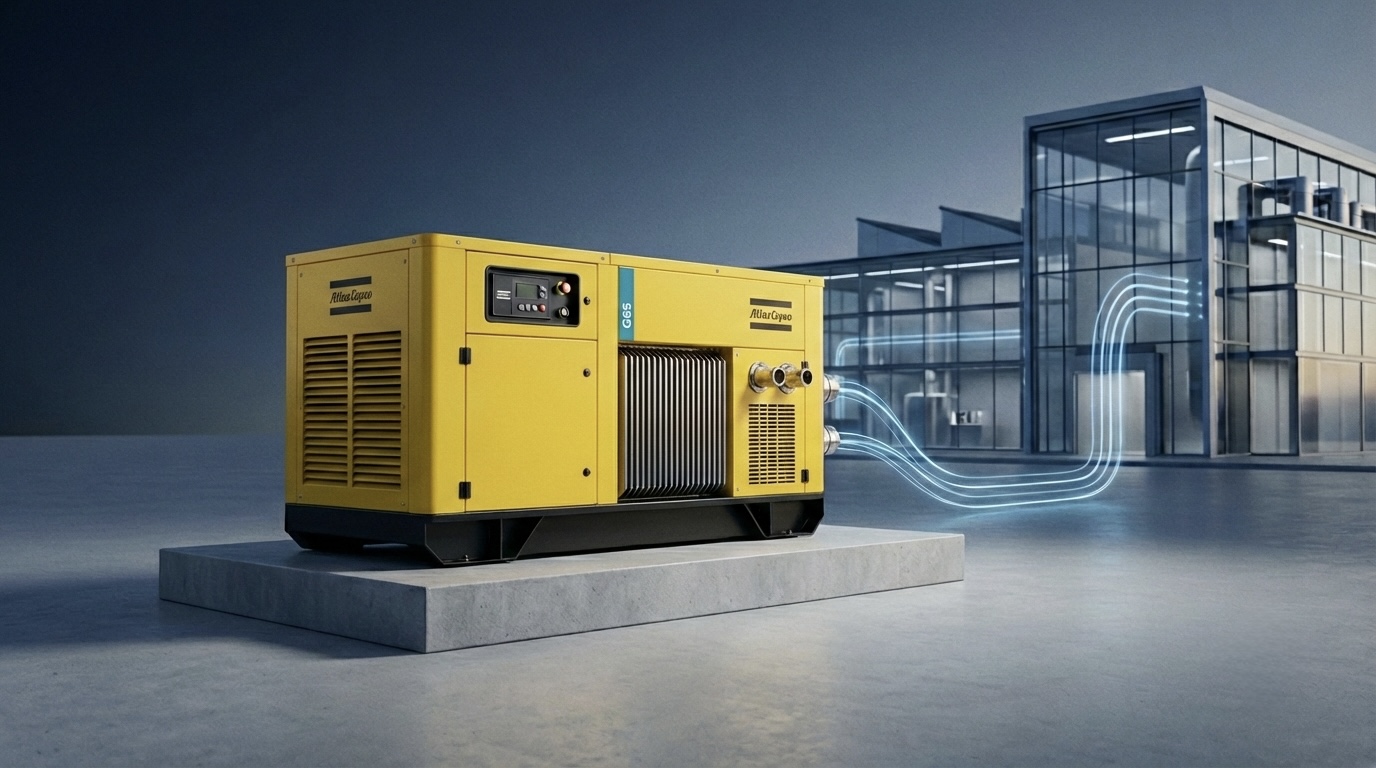

Manufacturing and industrial plants

Compressors in manufacturing plants are an integral part of the production line and often operate for long hours throughout the day. This puts energy efficiency at the forefront.

Screw compressors with a power of 30–90 kW and higher are recommended for such facilities. Systems equipped with variable speed drive (VSD) technology in particular significantly reduce electricity consumption as they operate according to air demand. Energy-efficient solutions from manufacturers such as Atlas Copco are widely used in this area.

Food, pharmaceutical and medical industries

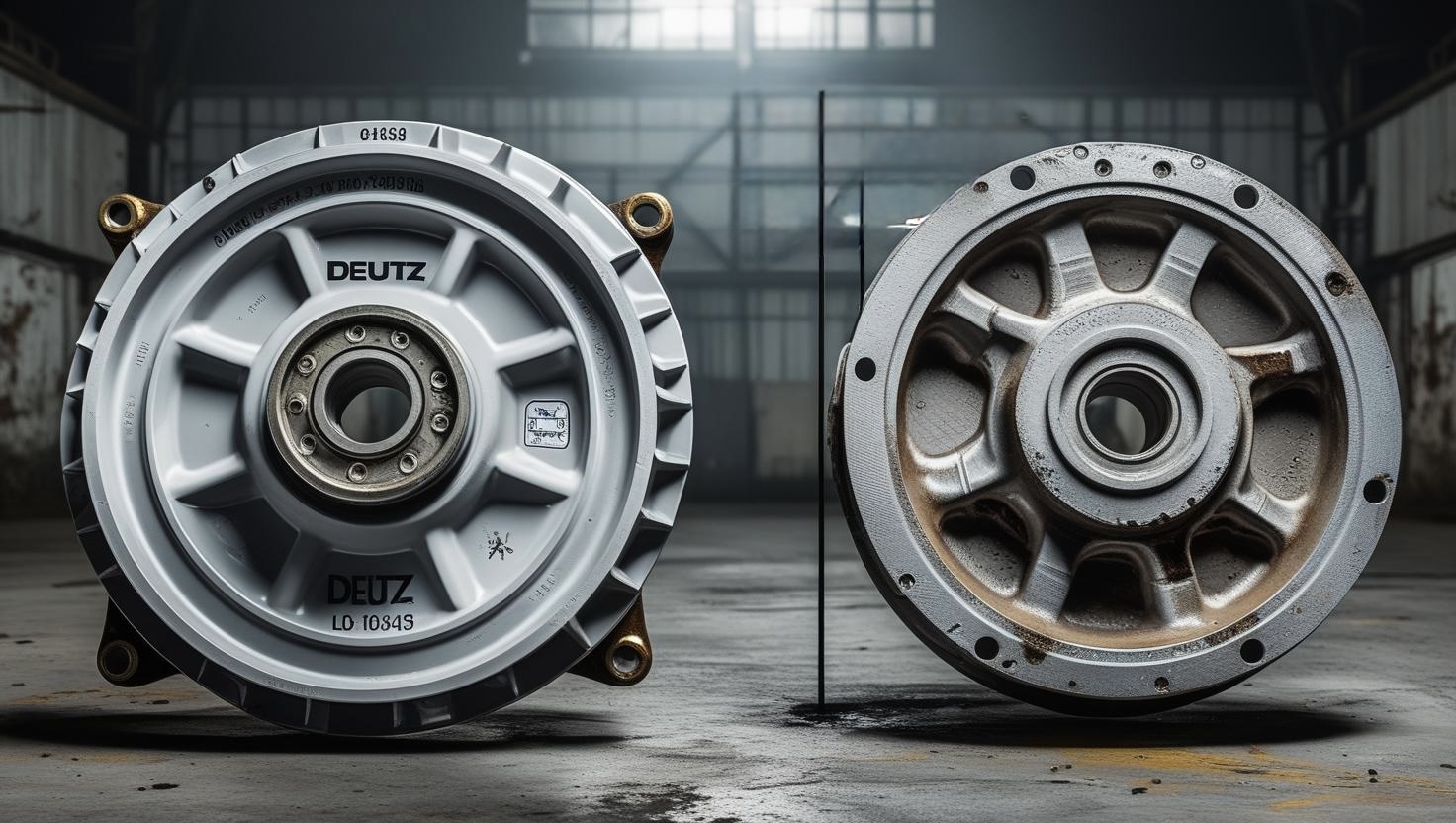

The choice of compressor in the food and pharmaceutical industries is not limited to power indicators alone. Here, the quality and purity of compressed air directly affect the safety of the product.

For this reason, oil-free compressors should be used in conjunction with additional filtration and drying systems. Oil-free screw compressors with a power range of 15–75 kW are usually considered the optimal choice for these areas. In these types of plants, air quality is a more important factor than power.

What risks does the wrong choice pose?

Choosing the wrong compressor for the wrong capacity and type can lead to unexpected production interruptions, rapid equipment failure, and increased costs. This means both financial loss and risk in the long term.

Conclusion

Compressor selection is a strategic decision for every enterprise. A properly selected compressor ensures uninterrupted production, reduces energy costs, and extends the life of the equipment.

Remember, the needs of each industry are different, and the most accurate result is achieved when a technical analysis is conducted in accordance with the conditions of use.