Compressed air systems are considered the “hidden powerhouse” of industrial production. However, one of the biggest and often overlooked problems with these systems is humidity (moisture). Humidity in compressed air can damage equipment, reduce production quality, and cause significant financial losses.

In this blog post, we explain in detail why humidity in compressed air is dangerous and how to prevent it.

Where Does Humidity in Compressed Air Come From?

Atmospheric air naturally contains water vapor. As the compressor compresses the air:

The air temperature rises

More water vapor enters the compressed air system

When the air cools, this vapor turns into condensate (water)

Resulting in:

In piping

In air tanks

Water collects in tools and equipment

The Dangers of Moisture in Compressed Air

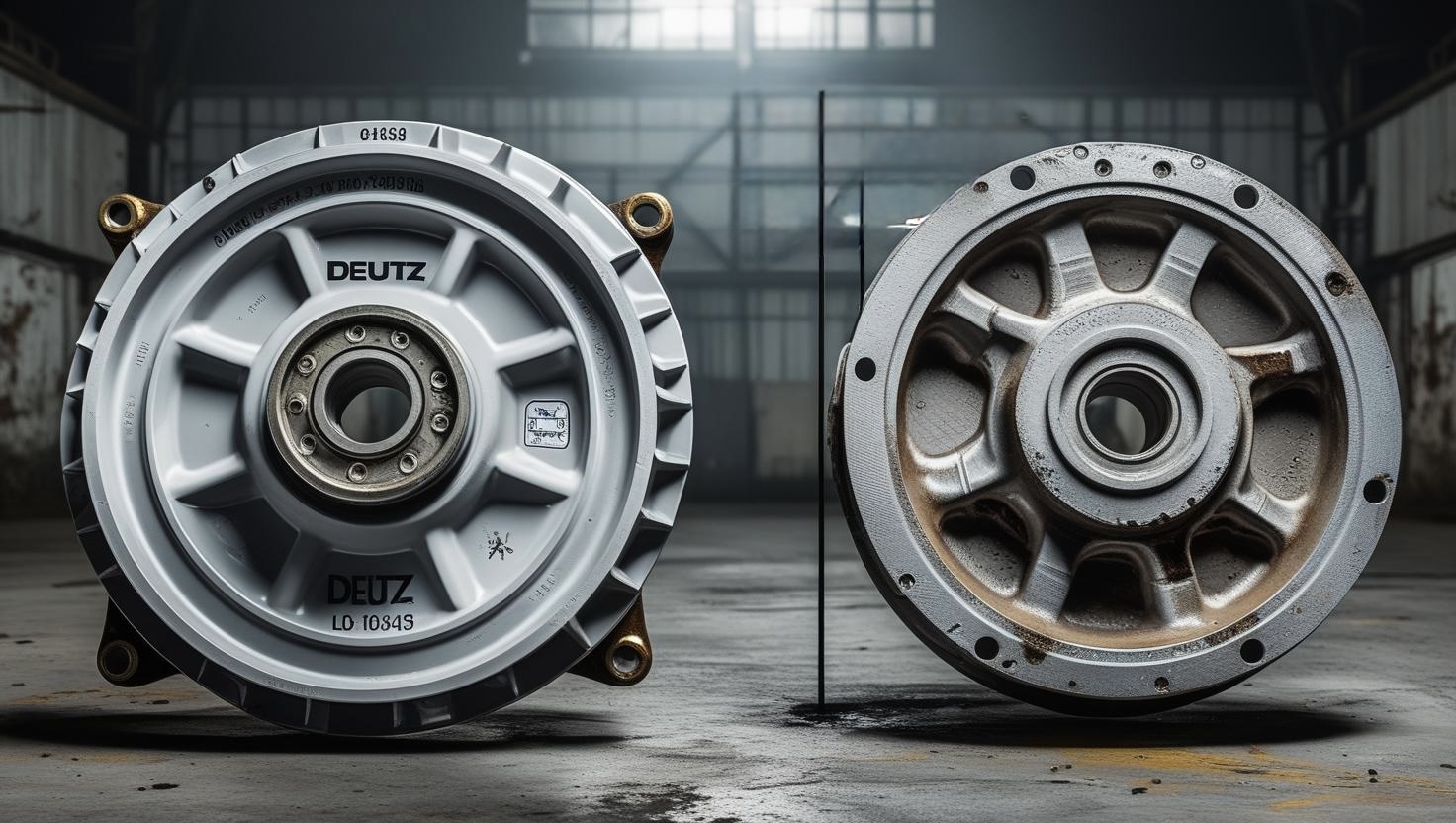

Equipment Corrosion

Moisture:

Causes metal pipes to rust

Failure of valves and fittings

Shortens the life of compressor components

This means additional service costs and production downtime.

Product Quality Deterioration

Humidity poses a serious risk, especially in these industries:

Food and beverage industry

Paint and surface coatings

Electronics manufacturing

Pharmaceuticals

Humid air:

Causes blistering and spots in paint

Causes contamination in the product

Leads to violation of quality standards

Pneumatic Tool Failure

Compressed air tools:

Not lubricated properly

Experience freezing and seizing

Failures more quickly

This means both safety risks and work delays.

Energy Losses and Increased Costs

A humid system:

Uses more energy

Filters fill up quickly

Compressor is loaded more heavily

Result: increased electricity costs

How to Prevent Humidity in Compressed Air?

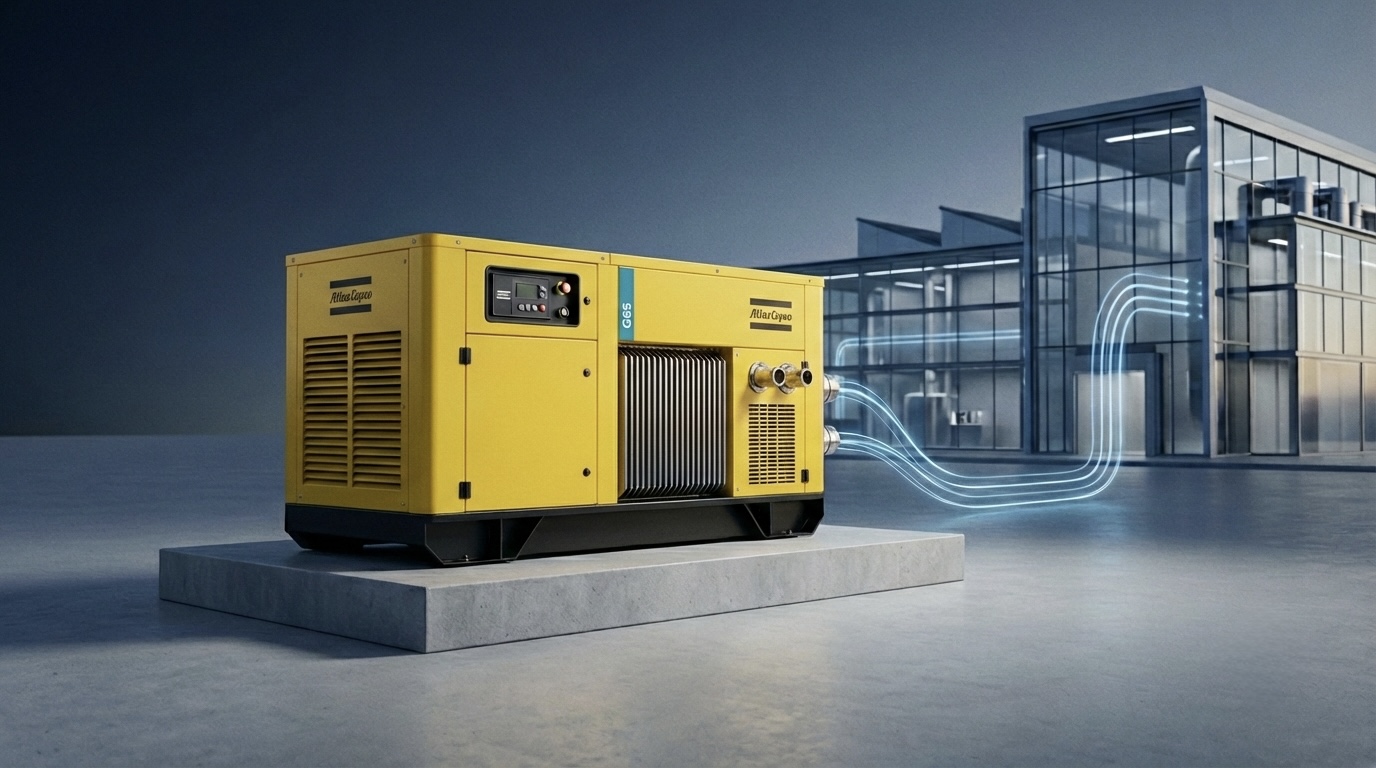

1. Using Air Dryers

The most effective solution against humidity:

Refrigeration type dryers – for general industrial use

Adsorption type dryers – for areas requiring high quality and dry air

These dryers dry the air by lowering the dew point.

2. Condensate Separators and Automatic Drains

Condensate is removed from the system in a timely manner

Water does not accumulate in the pipes

The system operates more stably

3. Proper Filtration System

A quality filter system:

Effectively separates water

Oil

Dust particles

This both protects the equipment and improves air quality.

4. Proper Compressor Selection and Design

The same system is not suitable for every area:

Air flow (m³/min)

Pressure (bar)

Area of use

must be analyzed correctly. Professional design minimizes the risk of humidity.

Conclusion

Humidity in compressed air:

Damages equipment

Reduces product quality

Increases energy and service costs

All of these risks can be avoided with the right dryer, filtration, and system selection